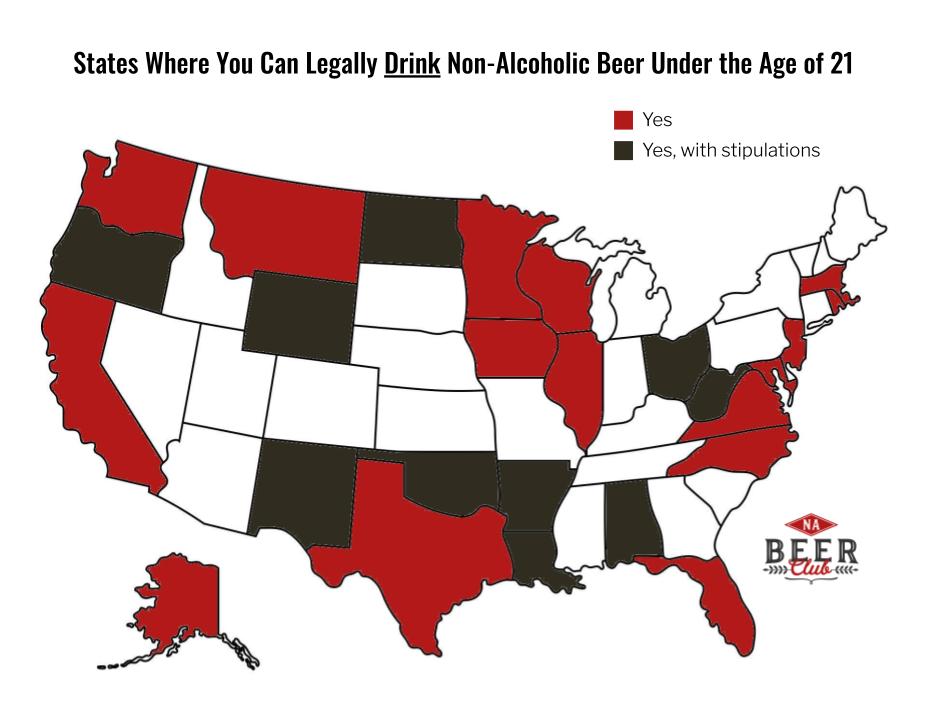

Critical Food Safety Violations: Immediate Closure Hazards in Restaurant Inspections

Understand critical food safety violations

Food safety inspections serve as the frontline defense against foodborne illnesses that affect millions of people yearly. Health inspectors have the authority to directly close food service operations when they encounter specific hazards that pose imminent danger to public health. These critical violations represent the virtually serious breaches of food safety protocols that can not wait for correction.

The distinction between routine violations and closure worthy hazards lie in the immediate risk they present to consumers. While minor infractions might receive citations or warnings, certain conditions trigger immediate cessation of food service operations to prevent potential illness outbreaks or contamination events.

Imminent health hazards lead to immediate closure

Sewage backup and cross contamination

Sewage backup represent one of the virtually serious violations that result in immediate closure. When wastewater systems fail and contaminate food preparation areas, the risk of pathogenic bacteria exposure become extreme. Raw sewage contain dangerous microorganisms include e. Coli, salmonella, and hepatitis viruses that can cause severe illness or death.

Cross contamination from sewage affect not entirely the immediate area but can spread throughout the facility through foot traffic, equipment, and air circulation. Flush after cleanup, extensive sanitization and testing are required before operations can resume.

Lack of potable water supply

Access to safe, drinkable water is fundamental to food safety operations. When the potable water supply is compromise, contaminate, or entirely unavailable, food preparation become impossible to conduct safely. Water contamination can introduce harmful bacteria, viruses, chemicals, or parasites into food products.

Restaurants require clean water for food preparation, cooking, clean equipment, handwashing, and sanitize surfaces. Without a reliable potable water source, these essential safety practices can not be maintained, create an imminent health hazard.

Power outages affecting temperature control

Extended power outage that compromise refrigeration and cooking equipment create dangerous temperature abuse conditions. When potentially hazardous foods enter the temperature danger zone between 41 ° f and 135 ° f for extended periods, bacterial growth accelerate speedily.

Perishable foods that have been temperature abuse can not be safely serve to customers, regular if power is restore. The inability to maintain proper hot and cold hold temperatures, cook foods to safe internal temperatures, or operate ventilation systems create multiple safety hazards simultaneously.

Pest infestations and contamination

Active rodent infestations

Evidence of active rodent infestations, peculiarly in food preparation or storage areas, constitute grounds for immediate closure. Fresh rodent droppings, gnaw marks on food packages, or live sightings indicate ongoing contamination risks. Rodents carry numerous diseases and can contaminate food through direct contact, droppings, urine, and hair.

The presence of rodents besides suggest broader sanitation failures and potential structural problems that allow pest entry. These infestations can spread quickly and contaminate large quantities of food products before detection.

Cockroach infestations in critical areas

Heavy cockroach infestations, specially in food preparation areas, storage rooms, or around equipment, create serious contamination hazards. Cockroaches carry pathogenic bacteria on their bodies and can transfer these organisms to food contact surfaces, utensils, and ingredients.

These pests are specially dangerous because they’re active during non-operational hours when detection is less likely, allow extensive contamination to occur unnoticed.

Temperature control failures

Refrigeration system breakdowns

Complete refrigeration system failures that result in potentially hazardous foods being hold at unsafe temperatures create immediate closure conditions. When cold storage units can not maintain temperatures at or below 41 ° f, perishable foods begin develop dangerous bacterial levels within hours.

The financial pressure to continue operations despite equipment failures sometimes lead establishments to take dangerous risks with food safety. Yet, serve temperature abuse foods can result in serious foodborne illness outbreaks affect multiple customers.

Hot holding equipment malfunctions

Hot hold equipment that can not maintain foods at 135 ° f or supra create similar dangers. Warm foods provide ideal breeding conditions for bacteria, and customers consume these products face significant health risks.

Steam tables, warm units, and heated display cases must function right to prevent bacterial growth in prepare foods await service.

Chemical contamination hazards

Improper chemical storage

Chemicals store supra or near food preparation areas, or clean products mix with food ingredients, create toxic contamination risks. Chemical poisoning can cause immediate severe illness or death, make these violations grounds for instant closure.

Source: themoviedb.org

Unlabeled chemical containers, improper dilution ratios, or chemicals store in food containers represent serious safety hazards that can not be correct while operations continue.

Cross contamination from cleaning products

When clean chemicals contaminate food preparation surfaces, equipment, or ingredients, the entire affected area become unsafe for food service. Chemical residues can cause burns, poisoning, or allergic reactions in consumers.

Employee health and hygiene violations

Employees work while ill

Food handlers work with symptoms of foodborne illness, peculiarly vomit, diarrhea, or fever, create immediate contamination risks. These employees can transmit pathogens to food products, surfaces, and other workers, potentially cause widespread illness outbreaks.

Management allow sick employees to work demonstrate a fundamental failure to understand food safety principles and prioritize public health over operational concerns.

Lack of handwashing facilities

Non-functional handwash stations or lack of access to proper handwash facilities prevent employees from maintain basic hygiene standards. Hand contamination is a primary vector for foodborne illness transmission.

Adequate handwashing require accessible sinks, soap, paper towels, and proper water temperature. When these elements are unavailable, employees can not perform essential hygiene practices.

Structural and environmental hazards

Ceiling leaks and water damage

Active ceiling leak over food preparation areas or storage spaces create contamination hazards from building materials, mold, and uncontrolled water sources. Water damage can harbor dangerous microorganisms and compromise the structural integrity of the facility.

Leak pipes, damage roofing, or condensation problems that can not be directly control pose ongoing contamination risks to food products and preparation surfaces.

Ventilation system failures

Non-functional ventilation systems that can not remove cooking vapors, maintain air quality, or control temperature and humidity create unsafe working conditions and food safety hazards. Poor air circulation can contribute to bacterial growth and cross contamination.

Food source and preparation violations

Unapproved food sources

Food obtain from unapproved sources, include home prepare items, unlicensed vendors, or recall products, represent a serious safety violation. These foods have not undergo proper safety inspections and may contain dangerous contaminants or pathogens.

Establishments must maintain proper documentation show all food products come from approve, license suppliers who follow safety regulations.

Unsafe food preparation practices

Dangerous food preparation practices such as use the same cutting boards for raw meat and ready to eat foods without proper sanitization, or prepare foods at unsafe temperatures, create immediate contamination risks.

These practices demonstrate fundamental failures in food safety training and can result in serious cross contamination events affect multiple menu items.

Documentation and permit violations

Operate without valid permits

Food service operations must maintain current health permits and licenses to operate lawfully. Expired permits or suspend licenses indicate the establishment has not meet ongoing safety requirements or has fail to address previous violations.

Operate without proper permits suggest a disregard for regulatory oversight and public safety standards.

Failure to maintain required records

Lack of temperature logs, clean schedules, or employee health documentation prevent inspectors from verify that safety procedures are being followed systematically. These records provide essential evidence that food safety protocols armaintainedin during non inspection periods.

Prevent closure through proactive management

Regular self inspections

Successful food service operations conduct regular internal inspections use the same criteria health inspectors apply. This proactive approach identify potential problems before they become critical violations require closure.

Management should address equipment maintenance, employee training, and sanitation procedures incessantly preferably than wait for official inspections to reveal problems.

Source: tvfanatic.com

Employee training and accountability

Comprehensive food safety training ensure all employees understand their role in prevent contamination and maintain safe operations. Regular training updates keep staffing inform about current safety requirements and proper procedures.

Clear accountability measures help ensure employees follow safety protocols systematically, flush during busy periods when shortcuts might seem tempting.

Equipment maintenance programs

Preventive maintenance schedules for refrigeration, cooking, and clean equipment help prevent sudden failures that could compromise food safety. Regular maintenance is far less expensive than emergency repairs or temporary closure.

Backup plans for equipment failures, include relationships with repair services and temporary equipment suppliers, help minimize disruptions when problems occur.

Recovery and reopening procedures

When closure occur, establishments must address all identify violations entirely before reopen. This process typically requires documentation show corrective actions have beentakene and may involvfollow-upup inspections to verify compliance.

The reopening process can take days or weeks depend on the severity of violations and the extent of corrective actions require. During this period, establishments lose revenue while continue to pay fix costs, make prevention air more economical than remediation.

Understand which food safety violations can result in immediate closure help food service operators prioritize their safety efforts and resource allocation. By focus on prevent these critical hazards, establishments protect both their customers and their business operations from serious consequences.

MORE FROM searchcritic.com